See more with the new Sonel KT series 500 cameras

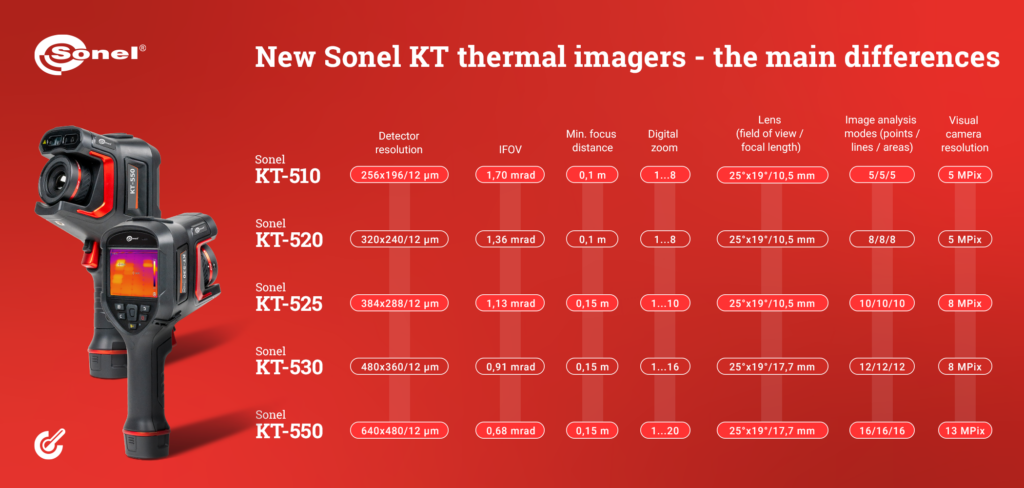

Resolutions from 256 x 192 to 640 x 480, manual and automatic focus, temperature range from -40°C to 650°C, IFOV from 1.70 to 0.68 mrad. Sonel is expanding its offer with five series 500 thermal imaging cameras. An ideal proposition for both seasoned and aspiring thermographers.

Use of thermal imaging cameras in the industry, electrical and HVAC sectors

Electricians, HVAC and RES technicians, professionals in the area of commercial power generation, industry and a number of other sectors are already using thermal imaging technology to help them better diagnose plant, machinery and equipment each day.

Thermal imaging is used in industry to reveal excessive heat loss, which is crucial for ensuring the energy efficiency of manufacturing processes. This allows insulation issues in industrial buildings to be identified and the temperature of machinery and equipment to be monitored, which is vital for preventing breakdowns and minimising downtime. In electrical engineering, thermal imaging cameras are used to detect overheating connections and components that may indicate a risk of failure or fire. In the HVAC sector, thermography is used to control heating, ventilation and air-conditioning systems for optimised operation and efficiency.

Customised thermal imaging cameras

The new Sonel KT-510 / KT-520 / KT-525 / KT-530 / KT-550 cameras are ideal for both intermediate and advanced users. One-handed operation for your convenience, a user-friendly interface and a 4.3″ touchscreen allow you to work efficiently and quickly under any conditions. With a wide range of resolutions (256 x 192 to 640 x 480), everyone can find a camera to suit their specific technical performance (e.g. IFOV) and price requirements.

Photograph 1. The new Sonel KT 500 series thermal imaging cameras

New image sharpening system

The new image sharpening system allows you to obtain excellent quality thermograms. You can choose between several autofocus modes: activated by a button located on the trigger, assisted by a laser rangefinder and two new features: continuous autofocus and image sharpening activated on the touchscreen (just like in a smartphone). Additional lenses are available for purchase for each camera to change its optical characteristics, allowing you to further customise your equipment. As a bonus, the lens is automatically configured when connected to the camera.

Photograph 2. Measuring with the new Sonel KT 500 series camera

Wide temperature range

The Sonel KT 500 series cameras can measure in two temperature ranges: -40°C…150°C and 0°C…650°C. You can manually select the range or use the automatic range selection mode. For the Sonel KT-520 / KT-525 / KT-530 / KT-550 models, you can extend the measured temperatures to a range of 500°C…2000°C by installing a high-temperature filter.

Photograph 3. Measuring with the new Sonel KT-500 series camera

Additional features of the new camera series

The new cameras are also equipped with GPS, a laser pointer, rangefinder and an LED flashlight. They also allow a report to be generated in the camera itself as well as text, voice and drawing notes to be added. The cameras are charged using a USB-C connector, in line with the latest standards, allowing for emergency charging of the camera while out in the field using a powerbank. Also included is a USB-C/RJ45 adapter if you want to use the Ethernet (LAN) interface to transfer files.

Fig. 1. The new Sonel KT 500 series cameras: main differences between models

Compact design

One big advantage of the Sonel KT 500 series cameras is their compact design. With the battery, the camera weighs approx. 1.15 kg. This allows you to work freely and efficiently under any conditions: in an industrial plant, on overhead lines, on a construction site, at RES and HVAC facilities – anywhere where fast and efficient diagnostics with high-end reliable equipment is required.

Author: Marcin Magierowski, Sonel S.A.

No Comment