Safety in photovoltaics with Sonel MPI-540-PV

The very rapid and dynamic development of photovoltaic installations that has been taking place in the world in recent years is impressive. It is largely due to the departure from traditional, non-renewable energy sources.

Greater social awareness and taking responsibility of the governments of individual countries for the climate around us forces the shift of the energy sector towards green energy. In addition, technology is constantly evolving, resulting in lower costs. If we add to this the constant increase in energy prices on the market, we will notice that the economic balance is more and more favourable for the photovoltaic sector. It is a key phenomenon in the context of further development of PV systems.

Unfortunately, the profitability of investments is often attempted to improve by lowering the quality, and hence – a decrease in the safety level of the photovoltaic installation itself (and thus an increase in the risk of operating and servicing the facility). For this reason, it is very important that the installation complies with all safety requirements after installation, and that its execution complies with applicable regulations. We can only be assured of this by carrying out appropriate tests and acceptance and periodic checks. The legal basis here is primarily the multi-sheet standard EN 62446, defining the method and scope of safety control of photovoltaic installations. Following the guidelines contained therein significantly reduces the risk of electric shock or fire. Measurements allow us to determine not only the safety but also the efficiency of a given installation and its elements.

Fig. 1. MPI-540-PV meter with accessories for measuring photovoltaic installations

The standard divides the tests into category 1 and 2 tests and additional tests. However, in order to be able to start the check at all, you must have the appropriate measuring instruments.

Sonel MPI-540-PV is a multifunction meter of parameters of electrical and photovoltaic installations. The device has been designed to meet the requirements of EN 61557 and EN 61010 standards, thus ensuring adequate accuracy and safety during work. The meter offers powerful possibilities in the field of electric shock protection tests and energy quality analysis, and we will successfully use it for category 1 tests defined by the EN 62446 standard, which include:

- continuity of protective connections

- earth resistance

- insulation resistance on the DC side

- open circuit voltage UOC

- short current ISC

- operating currents and powers on DC and AC side of the inverter

- the efficiency of the inverter

The standard requires that before starting category 1 measurements, all tests of the installation on the AC side should be performed. Their scope, in turn, is defined by the HD 60364 standard. The MPI-540-PV meter will also prove itself in this case.

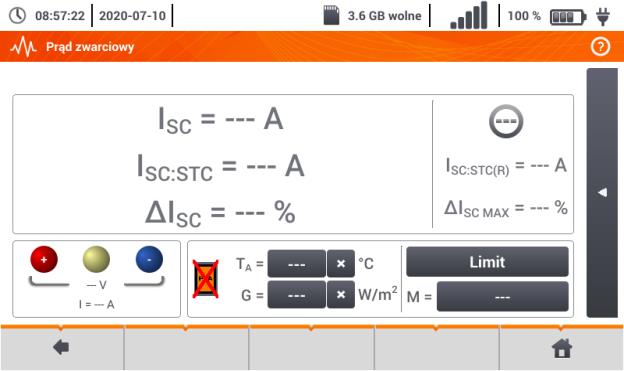

By measuring the parameters of the PV installation, such as the short-circuit current Isc or the open-circuit voltage Uoc, you can quickly verify the correct connections of the modules in the string, their polarity and operation. Measurements can be made for the entire chain of panels or for a single module.

The manufacturer usually specifies the parameters of individual elements of the PV system measured in STC (Standard Test Conditions: 25°C, 1000 W/m²).

For comparison purposes, the meter can automatically convert the results to STC conditions – the user only needs to enter additional data in the form of irradiance and temperature. In this case, you should save catalog parameters of photovoltaic panels in the module database located in the meter. It is necessary for conversions and for the evaluation of the measurement result.

Fig. 2. The screen of the MPI-540-PV meter showing the measurement of the short-circuit current ISC (left) and the open circuit voltage UOC (right) and their values converted to the STC conditions

The continuity of protective connections and the grounding resistance on the DC side are measured in the same way as in AC installations. In the case of insulation resistance tests, the difference is that the measurements are carried out under voltage, therefore special care should be taken. The values of operating currents and power on the DC and AC sides must be checked during the operation of both installations. Based on these measurements, we will verify the efficiency of the inverter and compare it with the efficiency declared by the manufacturer. Thanks to saving the results to the memory of the meter, they can be further used in the test report. A dedicated program for this purpose will be useful here: Sonel Reports PLUS.

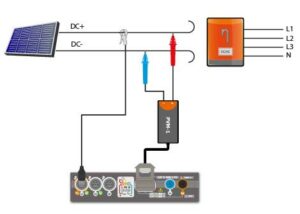

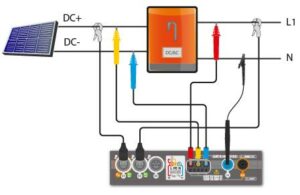

Sonel MPI-540-PV, apart from a huge number of measurement functions, has very rich equipment. It includes, among others accessories dedicated to testing photovoltaic installations: C-PV DC clamps, PVM-1 adapter ensuring safety and protection against electric arc, or adapters for MC4 connectors, commonly used in photovoltaics.

Together with the whole range of accessories and measuring possibilities, the meter is a valuable tool in the work of a measurement person. It will be especially appreciated by electrical installers performing acceptance measurements in electrical and photovoltaic installations.

Author: Tomasz Gorzelańczyk, Sonel S.A.

Products mentioned in the article:

No Comment