Energy-efficient lighting modernisation and measurement requirements

In an era of increasing electricity costs, influenced by, among other things, high inflation, legal conditions and ever higher energy production costs, individual consumers, businesses and local governments have been mobilised to seek solutions to reduce expenditure and electricity demand.

For some years now, one very popular way has been to replace lighting sources. After all, nothing feeds the imagination (and has a decisive influence on decisions to invest in energy efficiency) more than the vision of reduced bills. Is it really that simple? Let’s think about it.

Types of lighting sources

Light has been indispensable to humans for centuries and has an impact on the functioning of people, their environment and the functioning of workplaces. The most “healthy” light is natural light delivered optimally. One of its primary natural sources is, of course, the Sun, which emits energy as a result of the nuclear fusion reactions taking place within it. This energy reaches our planet in the form of radiation, i.e. a stream of electromagnetic waves and elementary particles. What we normally call light is that part of the electromagnetic radiation received by the retina of the human eye. Many years of research have made it possible to determine the wavelengths seen by the naked eye: this is a band in the range of approximately 380-780 nm.

Knowing what sunlight is and being aware of its impact on the functioning of life on Earth, mankind has sought to create its own lighting sources. For many years, the gloom and darkness were illuminated by torches and bonfires, followed by lamps for various oils and candles. Street lighting using oil lanterns was introduced in central London as early as 1668. The next great leap came in 1853, when the Polish pharmacist Ignacy Łukasiewicz invented the paraffin lamp in Lvov. Nowadays, various types of electric bulbs and LEDs are used on a large scale. Their development is ongoing and one of the main goals of this process is to produce a product that uses as little energy as possible while producing as much luminous flux as possible.

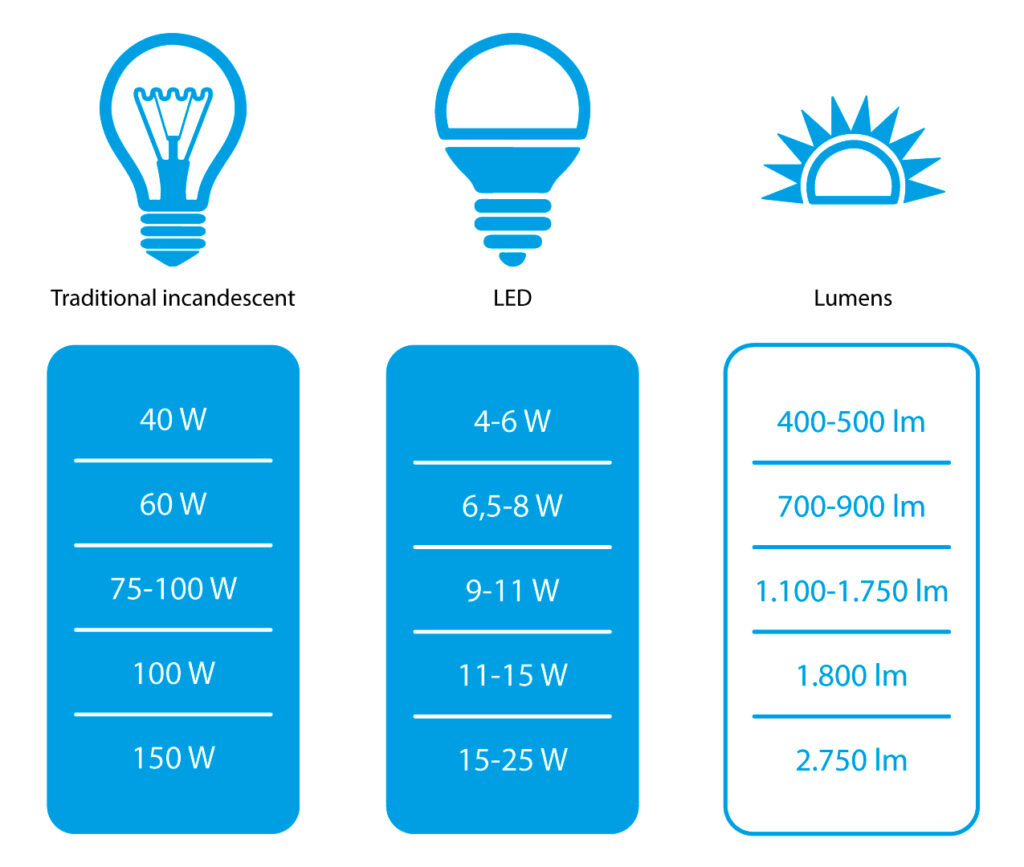

Today, lighting using LED light sources is the most popular. They are considered to be the most energy-efficient. In order to achieve the same luminous flux as a 9-watt LED bulb, a discharge (fluorescent) bulb would need to draw about 13 watts and a tungsten filament bulb about 70 watts.

The search for savings and lighting requirements

Given the increasing cost of living for households and the cost of running businesses and local governments, steps are being sought to limit the severity of these increases. One of these measures is the lightning modernisation. In the case of households, the most common change is from traditional incandescent bulbs to LED-type equivalents in the lighting source or luminaire itself. When making such changes, in addition to the price criterion, the following aspects should be taken into account in particular:

- the nature of the room in which the modernisation will take place,

- emitted luminous flux power,

- colour temperature,

- type of stem for the current lamp.

Additional attributes are:

- colour rendering (Ra) index,

- luminous flux angle,

- number of switching cycles,

- dimming capability,

- viability.

The results of modernisation are subject to the subjective assessment of the household’s residents. The wrong choice of lighting can have consequences in terms of the aesthetics of a room, the correct perception of colours, but also have a negative impact on the body’s wellbeing and performance.

However, if chosen correctly, it has the potential to give the room a new character, as well as having a positive impact on our comfort. In contrast, the costs will only be incurred once and will start to pay for themselves immediately in the form of lower electricity bills.

Fig. 1 Comparison of the power of traditional and LED light bulbs in terms of luminous flux

For businesses and other workplaces, the reasons for wanting to carry out lighting modernisations are primarily energy efficiency, increased productivity and workplace safety. The cost of electricity consumption required to light up the entire facility internally (workstations, corridors, they facilities) and externally (light illuminations, car parks, roads) is rising steadily. Unlike households, workplaces are subject to special regulations specifying lighting requirements (but, of course, aspects as for households are also relevant here).

An important first step before making changes is to carry out an energy audit of the company, which will include information on the inventory of the current distribution of luminaires and the types of sources used (including emergency lighting), the quality parameters of the existing electrical installation and the level of energy consumed (The audit will be supported by Sonel PQM series power quality analysers and multifunctional Sonel MPI installation parameter meters with a recorder module).

According to the guidelines laid down in EN 12464-1 and EN 12464-2 standard, illumination measurements should be carried out after a lighting modernisation in the following situations, among others:

- after changing the type of lighting, e.g. from fluorescent to energy-saving lighting, or after replacing used incandescent bulbs with new ones, but with a different power,

- after a change in the arrangement of the room, e.g. after the construction (or demolition) of partitions etc. in the room, when the illumination may deteriorate.

The use of appropriate measuring equipment is recommended to carry out such examinations. Sonel S.A. has as many as three models of illumination (illuminance) meters in its offer. These are Sonel LXP-2 dedicated to basic workstation and general lighting measurements), Sonel LXP-10B (also dedicated to emergency lighting measurements) and Sonel LXP-10A (providing the most accurate Class A measurements). The same measuring possibilities are also available with Sonel MPI-540-PV, Sonel MPI-540, Sonel MPI-530-IT and Sonel MPI-530 multifunctional installation parameter meters.

Fig. 2 Sonel LXP-2, LXP-10A, LXP-10B lux meters

Lighting is classified as a nuisance factor in the working environment. It is therefore important to bear in mind that the correct execution of illumination measurements, and consequently the results and actions taken in relation to them, will have an impact on the well-being of employees, their work performance and their level of focus and fatigue during work. Correct measurement will be ensured not only by the right equipment, but also by qualified measurement personnel. This is because they are required to have knowledge of photometric measurements in order for the results to be considered reliable and the work to be carried out in accordance with the construction art.

Local government units have been increasingly opting for partial or full lighting modernisation in urban and rural areas for several years. Such lighting consists, among other things, of motorised roads, pavements and cycle paths, squares, parks, etc. Many cities, towns and villages have for years been dominated by sodium lighting, which is now being replaced by modern LED solutions. Both sodium and led lighting sources have their supporters and opponents.

The advantages of sodium lamps include their greater luminous performance, i.e. the luminous flux (light output) in lumens obtained from 1 W of energy. However, the lm/W value alone does not reflect the actual stimuli perceived by the human eye – this is due to the very narrow light spectrum, i.e. the range of wavelengths emitted. Thus, sodium sources need to have a much higher luminous power to ensure proper visibility.

Another key aspect in the area of road lighting is the Colour Rendering Index (CRI), also referred to as Ra. It is recorded in numerical form in the range 0-100, where the higher the value, the better the colours are rendered. The value of 100 refers to white light and can be assumed to reflect natural sunlight, where the illuminated objects look natural. A CRI equal to 0 corresponds to monochromatic light and the visual experience is very poor, resulting in a distorted and unnatural image perceived by the human eye. This leads to a faster fatigue of the body through the increased work of the brain, which tries to correctly interpret the image coming through the eyes. Low- and high-pressure sodium lamps have a very low Ra of 10-25.

Meanwhile, LED-type sources for road lighting reach up to 90. They provide a broad band of the light spectrum, which has a lower power needed to provide the required visibility. Modern led lighting additionally has a much longer service life and a much lower rate of degradation over time (i.e. the rate at which the emitted luminous flux decreases). This has a direct impact on the need to replace or repair sources much less frequently.

Fig. 3 View of the road before and after the lighting modernisation

Before deciding to change from sodium to LED lighting, it is worth analysing all the parameters of the luminaires and sources, because juxtaposing only two selected features will not be reliable. It is worth remembering that the design of road lighting nowadays takes into account not only the fulfilment of lighting parameters, but also environmental aspects, the impact of lighting on the surroundings and issues relating to the appearance of the installation (aesthetics of lighting columns and luminaires, visual guidance or the colour temperature of lighting sources). When deciding on a lighting modernisation, it is important to ensure that the offers provided include:

- measurement and lighting design in compliance with regulations and standards,

- selection of luminaires, sourced from recognised manufacturers whose products have all the necessary certificates and approvals,

- removal of old luminaires and light sources, structures and sometimes even the electrical network infrastructure supplying the lighting, and installation of new elements.

An additional advantage is the assurance that the modernised lighting infrastructure will be maintained for the designated period.

It should be emphasised that current automation and control solutions for street lighting allow for free control and adjustment of, among other things, lighting illumination (luminous flux control) according to the time of day, the current weather or the decision of the infrastructure manager. There are a number of companies on the market that have focused the area of their services on this subject. When deciding on a lighting modernisation, it is worth considering a comprehensive approach to the subject and choosing an option that is more expensive but offers advanced possibilities for managing the entire installation. Such offers include:

- controlling the switching on and off of street lighting,

- adjusting the power of the emitted luminous flux and creating a schedule (profile) for the operation of individual street luminaires,

- creating and managing luminaire groups flexibly,

- creating maps with marked light points,

- measuring and recording energy consumption and archiving this data,

- alerting of incidents with indication of their location.

Based on a number of examples, the return on investment of replacing the lighting sources themselves with LEDs occurs after just a few years, and the savings can be seen in the form of lower electricity bills. Choosing to offer full road lighting management is a far better solution than hasty ideas such as completely switching off the lighting of entire streets or neighbourhoods. Plunging towns and villages into darkness can affect the safety and wellbeing of residents.

As with businesses, local authorities carrying out lighting modernisation should also carry out illumination measurements. One of the requirements of design or tenders is that illumination measurements must be taken and reports must be submitted after the examination have been carried out.

Only they will show whether the calculations and indications in the design and the execution of the modernisation work have had the intended effect. The report allows the electrical works manager to determine whether the work has been carried out correctly. The scope, criteria and method of road lighting measurements are defined in EN 13201 standard, especially the sheets:

- EN 13201-2 Road lighting – Part 2: Performance requirements,

- EN 13201-4 Road lighting – Part 4: Methods of measuring lighting performance.

Part two of the standard defines the lighting classes of the areas where the examinations are carried out and the allowable illumination and luminance values. In the fourth part, we find the conditions and measurement procedures for measuring the photometric quality parameters of road lighting installations, i.e. the parameters that quantify their performance according to the aforementioned classes. As in workplace measurements, road illumination examinations can be carried out with Sonel LXP and Sonel MPI-540-PV, MPI-540, MPI-530-IT and MPI-530 devices.

Active energy charges down and reactive energy charges up

It is important to remember that reducing active energy consumption when using LED-type sources is not the only element affecting electricity bills. After modernising lighting from traditional to led solutions, electricity meters will note the increased generation of capacitive reactive power. This is very important, because the energy seller’s regulations in the country in question can charge consumers for their generation and transmission to the power grid! In contrast, the generation of reactive inductive power will decrease.

To reduce or almost eliminate the generation of capacitive reactive power, the use of capacitor banks or reactors is recommended. Other solutions are intelligent reactive power control systems such as compensators, which modify the quality parameters of the network on the basis of current reactive power readings, using calculation algorithms and the operation of their components. This has a very good effect and directly affects reactive power charges. In order to correctly select a capacitor bank, reactor or compensator, an energy audit should be carried out using power quality analysers. Sonel S.A. has a whole series of analysers called PQM and MPI multifunction meters with an analyser module to do this reliably. The included Sonel Analiza 4 software, based on the results obtained, gives a complete insight into the situation and allows the selection of appropriate solutions to meet individual needs.

Summary

Companies, local authorities or household owners faced with rising electricity costs must take appropriate preventive measures. One of these measures is lighting modernisation. Traditional types of lighting source are being replaced by solutions based on LED technology, which is less energy-intensive and at the same time provides a visual experience with the potential for greater, flexible customisation. Like any change, this one also has positive and negative effects, of which the positive ones are far more numerous.

The decision on a lighting modernisation should be based on a prior examination, an energy audit, so that the chosen solution is the most appropriate to the needs and at the same time meets the expected objective: reducing electricity charges. Sonel S.A. has a range of tools which, with their measurement capabilities at every stage of modernisation, will support the work of all those involved: from solution architects to contractors to consumers. Choosing the right device and knowing how to use it correctly ensures that a complete lighting system modernisation is carried out correctly.

Author: Adam Szczepanik, Sonel S.A.

Products mentioned in the article:

No Comment